Cement Feeding System

- Home

- /

- Products

- /

- Conveying system

- /

- Cement Feeding System

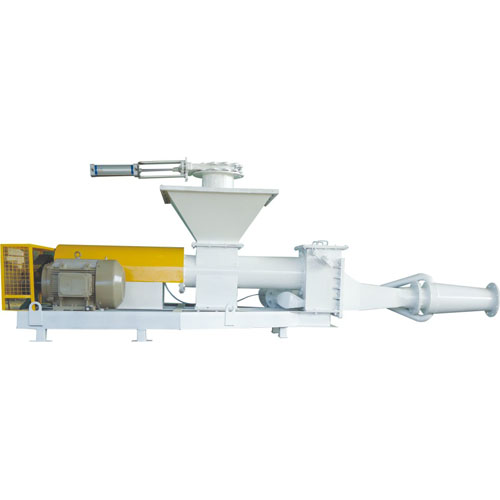

CEMENT FEEDING SYSTEM

Pneucon is considered as one of the very well trusted and leading Cement feeding system manufacturer that supplies huge range of Cement Feeding Systems. We provide finest quality products made out of superior components and raw materials acquired from the best suppliers in the market. To avoid complaints regarding the defects in the product the manufacturer severely keep check of the various parameters before the delivery of the product. These cement feeding system are known for their durability, strong construction with minimum maintenance cost and high performance.

The cement feeding system is the quickest as well as flexible method which is used to transfer the bulk material from a particular to point to another in a specific area. Pneucon is engaged in supplying huge range of such systems to the various construction sites across many destinations.

We manufacture hassle free performance giving systems and are one of the top Cement Feeding System Manufacturer Gujarat. The products manufactured by Pneucon are heavy duty as they are used mostly to transfer dry, crushed material from mills, free flowing, load the railcars and unload those and covey the dust from collectors. The materials can be transferred to anywhere.

See how our Products are Useful & Reliable:

The sophisticated machines provided by the company are very useful and reliable. The products are manufactured under high supervision of the professionals to ensure the safety and maintain the consistent quality of the products. The design of the cement feeding systems by Pneucon is compact and is rigid built and serves many clients in the market. This cement system manufacturer India will soon occupy the best position in market.

The material to be transferred goes into the hopper because of the gravity. The system is so developed that the material gets compacted. The density of the materials increases due to the space present in the front of the non-return valve and terminal of the screw flight in order to create a seal so that blowback is prevented. Later, the components go inside the discharge body and compressed air fluidizes it and is transferred in the transport line.

Pneucon holds an expertise in supplying strong and tough products with no corrosion assurance. The professionals in the company can deal with the queries of the customers and their requirements. Cement Feeding Systems are generally made of structured and mild steel which are placed on a base. FS pumps helps to operate smoothly as they possess pedestal blocks that are important to provide support to pump screw. The screw is very well balanced and made with an appropriate hard surfacing, wear resistant material and tough coating whenever required. The screw is connected directly with the motor.

The equipment used on FS pumps is standard and the assembly that handles the system is durable enough to extend the life of the materials used in manufacturing the product and avoids the problem. Every system of pump comes with a pump, a motor and a source of air that is compressed.

Following Accessories Included

- Suction Silencer

- Discharge Silencer

- Spring Loaded safety Valve

- Pressure gauge

- Suction Filter

- Driven Pulley

- Non Return Valve

- V-Belt Set

- V- Belt Guard

- Drive Pulley

Salient Features

- Closed System

- Ensures contamination free transfer for material

- No Spillage or wastage involved

- Minimum Maintenance

- Speedy & User friendly designs

| SR. | ITEM DESCRIPTION | SPECIFICATION | |

| 01 | MODEL | PSP-I | PSP-II |

| 02 | OUTPUT CAPACITY* | 12-15 TON/HR | 20-25 TON/HR |

| 03 | FEED HOPPER CAPACITY | 500 Kg | 700 Kg |

| 04 | SCREW | TOUGHEND | TOUGHEND |

| 05 | SCREW MOTOR | 22.5 kW / 30 HP | 22.5 kW / 30 HP |

| 06 | TWIN LOBE AIR BLOWER | PI-19 | PI-22 |

| 07 | BLOWER MOTOR | 30 kW / 40 HP | 37.5 kW / 50 HP |

| 08 | STRUTURE | WITH WHEEL/ANTI VIBRATION PAD | WITH WHEEL/ANTI VIBRATION PAD |

| 09 | POWER SUPPLY | 415 V AC ± 10%, 3 PHASE, 50 HZ ± 5% | |